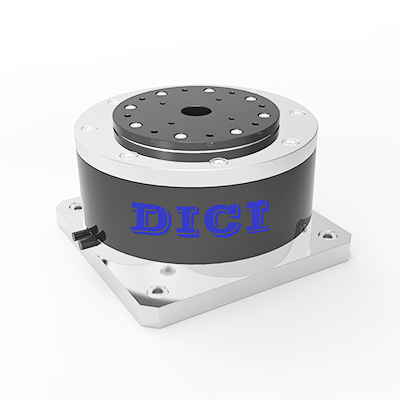

DICI DD motor torque motor is a special motor with soft mechanical characteristics and wide speed range. When the load of the motor increases during operation, the speed of the motor automatically decreases, increasing the output torque, and maintaining the load balance of the motor. It has soft mechanical characteristics that can block rotor, high locked rotor torque, small locked rotor current, and can withstand locked rotor operation for a certain time.

As the rotor has high resistance and large loss, the heat generated will be large. If it is in low speed operation and locked rotor, the loss will be larger and the heat will be higher. Therefore, in this case, the rear cover of the motor shall be equipped with a centrifugal fan or axial flow fan with an output torque greater than 100 for ventilation and cooling. When the load torque increases, the speed can be automatically reduced and the output torque can be increased. When the load torque is a certain value, change the motor terminal voltage and then adjust the speed, but the speed adjustment rate is not good. Then add a speed measuring device on the motor shaft, equipped with a controller, and use the voltage output by the speed measuring device and the voltage given by the controller to adjust the motor terminal voltage to stabilize the motor. It can also be equipped with a silicon controlled device to adjust the voltage and speed. Generally, the speed range can reach 1:4, and the speed change rate is ≤ 10%.

As the rotor has high resistance and large loss, the heat generated will be large. If it is in low speed operation and locked rotor, the loss will be larger and the heat will be higher. Therefore, in this case, the rear cover of the motor shall be equipped with a centrifugal fan or axial flow fan with an output torque greater than 100 for ventilation and cooling. When the load torque increases, the speed can be automatically reduced and the output torque can be increased. When the load torque is a certain value, change the motor terminal voltage and then adjust the speed, but the speed adjustment rate is not good. Then add a speed measuring device on the motor shaft, equipped with a controller, and use the voltage output by the speed measuring device and the voltage given by the controller to adjust the motor terminal voltage to stabilize the motor. It can also be equipped with a silicon controlled device to adjust the voltage and speed. Generally, the speed range can reach 1:4, and the speed change rate is ≤ 10%.

沪公网安备31011402007408号

Tel